Root Cause Analysis: Find the Real Reason Behind Medication Issues

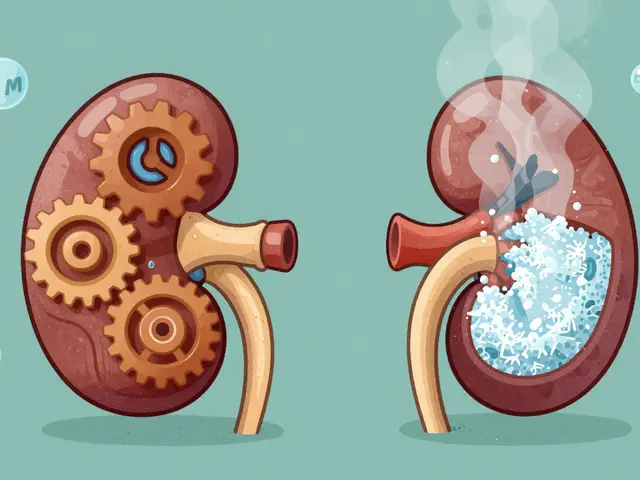

When a patient has a bad reaction to a drug, it’s rarely just one mistake. Root cause analysis, a systematic method to trace problems back to their origin. Also known as RCA, it’s how pharmacies and hospitals figure out why things went wrong—not just what went wrong. This isn’t about blaming someone. It’s about finding the broken step in the chain: Was the label misprinted? Did the pharmacist miss a drug interaction? Did the patient misunderstand the instructions? RCA looks at the whole system.

Take a case where an older adult ended up in the hospital with low sodium. At first, it looked like an SSRI side effect. But RCA showed the real issue: the patient was taking three different meds that all lowered sodium, and no one checked the combo. That’s why adverse drug reactions, unexpected harmful effects from medications don’t always show up in clinical trials—they happen when multiple factors line up. Similarly, medication errors, mistakes in prescribing, dispensing, or taking drugs often come from poor communication, rushed workflows, or unclear labels. And pharmacy safety, the practices that keep patients safe from harm depends on catching these patterns before they hurt someone.

Most of the posts here aren’t just about drugs—they’re about how things go wrong and how to fix them. You’ll find breakdowns of dangerous drug combos, how the FDA tracks hidden risks, why people stop taking generics because of cultural beliefs, and how lab tests can catch problems early. These aren’t random stories. They’re all pieces of a bigger puzzle: how systems fail, and how we can make them stronger. Root cause analysis isn’t just for hospitals. It’s for anyone who takes meds, fills prescriptions, or cares about getting safe care. The next time you hear about a drug recall or a side effect warning, ask: what’s the real reason behind it? The answers are here.

How Manufacturers Fix Quality Problems: A Practical Guide to Corrective Actions

Manufacturers fix quality problems by finding root causes, not just symptoms. Learn how CAPA systems, root cause analysis, and verification steps reduce defects, ensure compliance, and prevent recurrence in regulated industries.

view more