When a car part breaks after just 500 miles, or a medicine bottle is mislabeled, or a surgical tool arrives with a scratch - it’s not just a mistake. It’s a signal. And smart manufacturers don’t just fix the symptom. They dig deeper. That’s where corrective actions come in.

What’s the difference between a fix and a corrective action?

Many people think fixing a problem means stopping the line, throwing out bad parts, or tweaking a machine setting. That’s a correction. Quick. Simple. Temporary. A corrective action is different. It asks: Why did this happen in the first place? And then it changes the system so it can’t happen again. Think of it like this: If your car’s tire keeps going flat, putting air in it is a correction. Finding out the nail is still stuck in the tread and removing it? That’s a corrective action. In manufacturing, especially in regulated industries like medical devices or pharmaceuticals, skipping the real fix can cost millions - in recalls, lawsuits, or even lives. The FDA issued over 200 warning letters in 2022 alone because companies didn’t properly fix their root causes. Most of those letters said the same thing: "You fixed the part. You didn’t fix the process."The six-step process manufacturers actually use

There’s no magic formula, but there is a proven structure. Here’s how it works in real factories:- Identify the problem - It starts with data. A quality inspector spots a batch of components outside tolerance. A customer returns 12 units with the same defect. A sensor on the assembly line triggers an alert. The event is logged - no exceptions.

- Evaluate the risk - Not all problems are equal. Is this a safety issue? Could it affect patient health? Does it break a regulatory rule? High-risk issues get top priority. Low-risk ones might be handled differently.

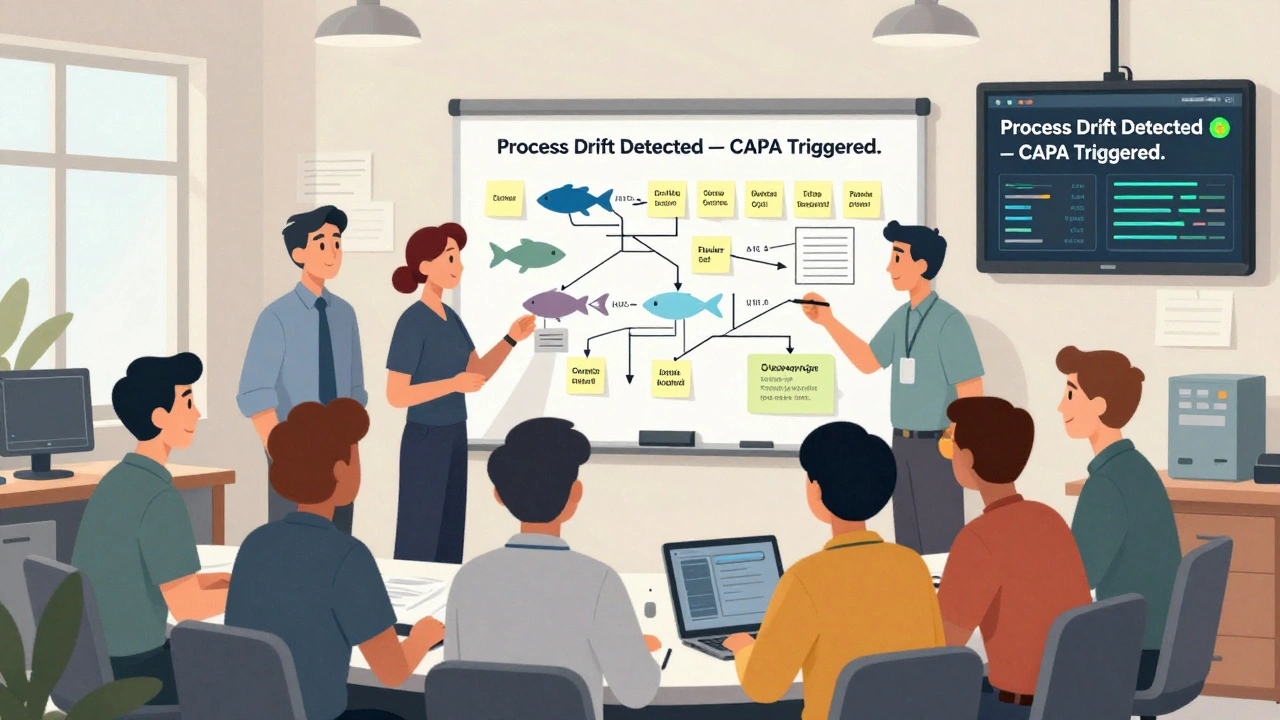

- Find the root cause - This is where most companies fail. They guess. Or they blame the operator. The best teams use tools like the 5 Whys or Fishbone diagrams. For example: Why did the seal fail? → The adhesive didn’t cure. Why? → The oven temperature dropped. Why? → The thermostat was mis-calibrated. Why? → No one checked it in 9 months. Why? → There was no scheduled maintenance in the work order system. There’s your root cause.

- Plan the fix - Now you write it down. Who does what? By when? How will you know it worked? A good plan includes specific actions, deadlines, names, and how you’ll test the solution. No vague stuff like "improve training" - instead, "train all shift supervisors on thermostat calibration by March 15, using the updated SOP version 3.2."

- Implement the fix - Changes get rolled out. Machine settings are updated. Work instructions are revised. People are trained. Tools are recalibrated. Everything is documented. No exceptions.

- Verify it worked - This is non-negotiable. You don’t just assume it’s fixed. You test it. You run 30+ units through the process. You check the defect rate before and after. You use statistical process control charts. You look for trends over time. If the defect rate doesn’t drop by at least 50% within three production cycles, you go back to step three.

Why most corrective actions fail

You’d think this process is straightforward. But here’s what happens in practice: - 61% of companies that get inspected by the FDA fail because they only fix the symptom, not the cause. They replace a broken part but don’t fix why it broke. - 57% of failed corrective actions skip proper root cause analysis. They go straight to "train the operator" - even when the operator wasn’t the problem. - 38% don’t have clear ways to verify the fix. They say "it’s better now," but they have no data to prove it. - 65% of quality managers say the paperwork is overwhelming. One system generated 47 pages of documents for a single defect. That slows everything down. The biggest mistake? Treating corrective actions like a form to fill out, not a problem-solving tool.

What works in real factories

The companies that get this right share a few habits: - They use cross-functional teams. Quality, engineering, production, maintenance - all in the room together. No silos. One person can’t fix a machine problem if they don’t understand how the machine is used. - They tie CAPA to real-time data. Instead of waiting for someone to spot a defect, they use sensors and software to catch issues as they happen. AI tools now analyze production data to predict when a process is drifting - and auto-trigger a corrective action before a single bad part is made. - They keep it simple. In small-batch manufacturing, a 10-page CAPA form is overkill. They use checklists, photos, and digital notes. The goal isn’t paperwork - it’s prevention. - They track results. Successful manufacturers don’t just close the case. They monitor defect rates for 6 months. They compare performance before and after. They celebrate when a problem doesn’t come back. One automotive supplier in Michigan cut their defect rate from 2.8% to 0.4% in 18 months - not by hiring more inspectors, but by fixing 12 root causes in their welding process. Each fix took 8-12 hours of focused analysis. They didn’t rush it.Regulations aren’t the enemy - they’re the map

You hear people complain about FDA, ISO, or cGMP rules. But here’s the truth: those rules exist because someone died because a company skipped the steps. Medical device manufacturers must follow ISO 13485. Pharmaceutical companies must meet cGMP. Both require documented evidence that corrective actions eliminated the root cause - not just the symptom. The good news? Compliance isn’t a burden - it’s a competitive advantage. Companies with strong CAPA systems see 27% fewer field recalls and 34% less scrutiny from regulators. That means less downtime, fewer audits, and more trust from customers.

The future: Predictive corrective actions

The next big shift isn’t about fixing problems after they happen. It’s about stopping them before they start. Manufacturers are now using AI to monitor thousands of data points in real time - vibration, temperature, pressure, cycle time. When a pattern emerges that matches past failures, the system flags it. It doesn’t wait for a defect. It triggers a corrective action automatically. Gartner predicts that by 2027, 65% of manufacturers will use these predictive systems. That could cut quality-related downtime by nearly half. It’s not science fiction. It’s happening now. One medical device maker in Germany reduced their corrective actions by 40% in just 10 months - not because they had fewer problems, but because they stopped the problems before they happened.What you should do today

If you work in manufacturing and you’re still treating quality issues as one-off fixes, here’s your starting point:- Take one recurring defect. Not the biggest one. The one that keeps coming back.

- Gather your team: production, quality, maintenance.

- Ask "Why?" five times. Write down every answer.

- Don’t stop until you find a process, not a person, at fault.

- Write a simple plan: who, what, when, how you’ll check.

- Run 30 units. Measure the result. If it’s not better, try again.

What’s the difference between correction and corrective action?

Correction is a quick fix - like throwing out bad parts or adjusting a machine setting. Corrective action digs deeper to find and fix the root cause so the problem doesn’t happen again. One stops the symptom; the other stops the disease.

Do all manufacturers need a formal CAPA system?

If you’re in a regulated industry - medical devices, pharmaceuticals, aerospace, or automotive - yes. ISO 13485, FDA, and IATF 16949 require it. For small-batch or low-risk manufacturing, a simpler process with clear documentation is enough. The key isn’t complexity - it’s consistency.

How long should a corrective action take?

There’s no fixed timeline, but root cause analysis alone often takes 8-12 hours per issue. The whole process - from discovery to verification - can take weeks. Rushing it leads to failure. The goal isn’t speed. It’s effectiveness. If you haven’t seen the defect rate drop after three production cycles, you haven’t fixed it yet.

Can software help with corrective actions?

Yes. Digital CAPA systems reduce documentation time by up to 41% and help track verification results automatically. Tools that connect to production sensors can even trigger corrective actions before a defect occurs. But software doesn’t replace thinking - it supports it.

What happens if you don’t do corrective actions?

You’ll keep making the same mistakes. Defects pile up. Customer complaints rise. Costs climb. In regulated industries, you risk FDA warning letters, product recalls, or even shutdowns. The most common reason for FDA citations is poor CAPA implementation - not bad products, but bad processes.

How do you know a corrective action actually worked?

You measure it. You compare defect rates before and after. You run at least 30 units through the revised process. You use control charts to track stability over time. If the defect rate drops by more than 50% and stays down for three full production cycles, you’ve got a winner. Guessing isn’t enough.

10 Comments

So many companies treat CAPA like a box to check. But it’s not about paperwork-it’s about culture. If your team fears blame, they’ll hide mistakes. Real change starts when leaders say, 'Tell me what broke, not who broke it.' I’ve seen teams turn around when the focus shifted from punishment to curiosity. It’s wild how much better things get when people feel safe to speak up.

Also, the 5 Whys? Still the most underrated tool. Just keep asking until you hit something systemic. Not the operator. Not the weather. The system.

Of course they say 'fix the system'-but who’s really behind these 'corrective actions'? Big Pharma and defense contractors pushing compliance theater so they can keep raking in billions while workers get blamed for 'human error.' The FDA? A rubber stamp. The real root cause? Profit over people. They don’t want to fix the system-they want to fix the PR.

USA makes the best medical devices. Period. All this 'root cause' nonsense is just Europe and India trying to copy us while complaining about paperwork. We don’t need 6 steps. We just need competent people who don’t let bad parts slip out. If you’re losing sleep over a scratched tool, maybe you’re in the wrong industry.

5 Whys works. But most managers skip to step 4. They write the fix before they even understand the problem. Then they wonder why it comes back next month. Simple. Do the work. Or don’t bother.

AI predicting defects? That’s just tech bros selling snake oil. Real manufacturing doesn’t need fancy software. It needs hard workers who care. All this data obsession? Just a distraction from the real issue: lazy management and bad hiring. Fix the people, not the sensors.

I’ve spent 18 years in medical device QA, and I can tell you this: the most successful teams aren’t the ones with the fanciest CAPA software. They’re the ones where the machine operator feels comfortable walking up to the quality engineer and saying, 'Hey, I think the torque setting is off.' That’s the magic. No forms. No meetings. Just trust. And that trust? It’s built one honest conversation at a time. When you stop treating people like liabilities and start treating them like sensors-because they are-you stop having the same problems over and over. I’ve seen it. A team in Ohio cut their defects by 80% in six months just by letting people speak up. No AI. No consultants. Just listening.

Anyone who thinks corrective actions are 'just paperwork' has never worked in a regulated environment. You think this is optional? Wake up. People die when this is ignored. If you’re cutting corners because 'it’s too much work,' you’re not a professional-you’re a liability. And yes, the paperwork is tedious. So is brushing your teeth. Do it anyway.

Stop the hype. Just fix the damn thing.

THIS IS WHY AMERICA IS LOSING INDUSTRY!!!

They want us to sit in meetings for 12 hours analyzing why a screw came loose?! Meanwhile, China is making 10,000 units an hour with robots and zero paperwork!!

They don’t care about 'root causes'-they care about output!!

Our 'quality systems' are killing us!!

Why are we still using 1980s thinking?!

Someone needs to wake up!!

Someone!!

PLEASE!!

While the procedural framework outlined is methodologically sound, one must interrogate the epistemological underpinnings of root cause analysis as a hegemonic construct within Western industrial paradigms. The 5 Whys, for instance, presumes linearity in causality-a flawed ontological assumption when applied to complex adaptive systems such as modern manufacturing ecosystems. Furthermore, the implicit valorization of documentation as a proxy for efficacy constitutes a performative compliance ritual, divorced from material outcomes. One might posit that the true corrective action lies not in procedural adherence, but in the decolonization of quality assurance frameworks, integrating indigenous knowledge systems of craftsmanship and tacit expertise, which have historically eschewed formalized CAPA in favor of embodied mastery. Until such a paradigm shift occurs, we remain mired in bureaucratic palliatives.