Quality Control in Pharmaceuticals: What You Need to Know About Safe Medications

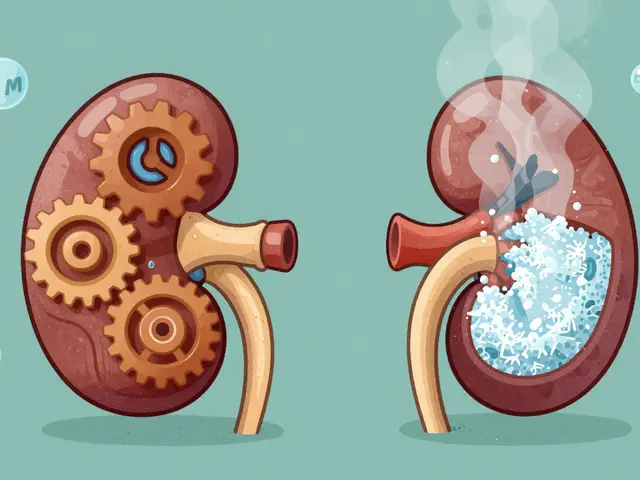

When you take a pill, you trust it’s exactly what the label says. That trust doesn’t come from luck—it comes from quality control, the systematic process of ensuring medications meet strict safety, strength, and purity standards before they reach patients. Also known as pharmaceutical manufacturing standards, it’s the invisible guardrail that stops contaminated, weak, or wrong drugs from ending up in your medicine cabinet.

Without quality control, even a well-known brand could be dangerous. Think about it: a batch of pills might have the right ingredient, but if the dosage is off by 10%, it could cause harm—or do nothing at all. That’s why agencies like the FDA don’t just approve drugs once. They keep watching. Through inspections, lab testing, and systems like MedWatch and Sentinel, they track problems after a drug hits the market. This isn’t theory—it’s daily work. In 2023 alone, the FDA issued over 1,200 warning letters to manufacturers for failing to meet quality standards. Some of those companies made generics you’ve probably taken. The difference between a safe generic and a risky one? It’s all in how well they control the process.

Quality control isn’t just about the final product. It starts with raw materials, flows through clean rooms and automated fillers, and ends with batch testing. Even small things matter—like whether the pill coating dissolves at the right speed, or if the machine that counts tablets is calibrated correctly. And it’s not just the big names. Many generic drugs are made in the same factories as brand-name ones, but without the same marketing. That’s why the FDA inspections, unannounced checks on manufacturing sites to verify compliance with Good Manufacturing Practices are so critical. They’re the only way to know if a company is cutting corners. Meanwhile, generic drug safety, the assurance that a generic performs the same as its brand-name counterpart isn’t just a claim—it’s backed by real-world data from millions of prescriptions and adverse event reports.

What you’ll find in these articles isn’t just technical jargon. It’s real stories: how a faulty tablet press led to a recall, why some people react badly to a generic because of an unlisted filler, how a lab missed a toxic impurity, and how the FDA finally stepped in. You’ll learn how to spot red flags in your meds, what to ask your pharmacist, and why a cheap drug isn’t always a good deal. These aren’t hypotheticals—they’re documented cases that changed how drugs are made and monitored. If you take any medication regularly, this isn’t just background info. It’s protection.

How Manufacturers Fix Quality Problems: A Practical Guide to Corrective Actions

Manufacturers fix quality problems by finding root causes, not just symptoms. Learn how CAPA systems, root cause analysis, and verification steps reduce defects, ensure compliance, and prevent recurrence in regulated industries.

view more