Manufacturing Quality: What Makes a Drug Safe and Reliable

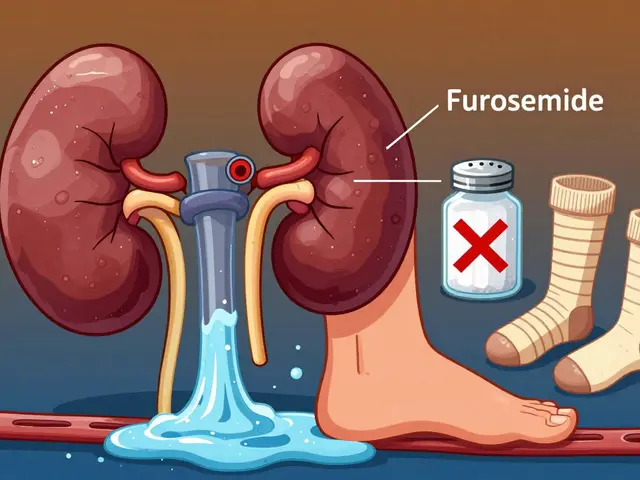

When you take a pill, you expect it to work the same way every time. That’s not luck—it’s manufacturing quality, the set of practices and controls that ensure medicines are made safely, consistently, and to exacting standards. Also known as pharmaceutical manufacturing standards, it’s the invisible backbone of every medication you buy, whether it’s brand-name or generic. Poor manufacturing can mean pills that don’t dissolve, contain the wrong dose, or even have toxic contaminants. And it’s not just about big pharma—generic drugs, which make up over 90% of prescriptions in the U.S., are held to the same rules. The FDA, the U.S. agency responsible for overseeing drug safety and approving manufacturing processes doesn’t just approve a drug once and walk away. They inspect factories, review data, and monitor complaints through systems like MedWatch and Sentinel. If a company cuts corners, the FDA issues warning letters, halts production, or pulls products off shelves.

Manufacturing quality isn’t just about the final pill. It starts with the raw ingredients, the cleanliness of the equipment, the training of workers, and even the humidity in the room where tablets are pressed. Generic drug safety, the assurance that a generic version performs the same as its brand-name counterpart depends entirely on this. A 2024 FDA report found that over 60% of drug-related recalls came from manufacturing flaws—not because the active ingredient was wrong, but because the process wasn’t controlled. That’s why you see stories about contaminated heparin, unlabeled pills, or batches with too much or too little medicine. These aren’t accidents. They’re failures in pharmaceutical standards, the formal guidelines that dictate how drugs must be produced to be legal and safe. The FDA compliance, the ongoing adherence to these rules by manufacturers is what keeps you from getting a counterfeit pill disguised as your blood pressure med.

What you’ll find in this collection isn’t just theory. These articles show you how manufacturing quality affects real people: how the FDA tracks problems after a drug hits the market, why some generics are made by the same companies that make the brand version, how cultural myths about pill appearance can make people distrust safe meds, and what happens when a factory fails an inspection. You’ll see how a single batch of contaminated medicine can ripple through the system—and how systems like FAERS and the authorized generics list help protect you. This isn’t about industry jargon. It’s about knowing that your medicine is what it says it is. And that’s not something you should ever take for granted.

How Manufacturers Fix Quality Problems: A Practical Guide to Corrective Actions

Manufacturers fix quality problems by finding root causes, not just symptoms. Learn how CAPA systems, root cause analysis, and verification steps reduce defects, ensure compliance, and prevent recurrence in regulated industries.

view more